Railway Brake Pad Manufacturers in China

Kingrail Parts friction products are famous for ensuring reliable stop. Kingrail Parts was founded in Maanshan (China) in 2007. It is a company that manufactures railway brake pads.

High - end organic LCC and high temperature brake pads

Kingrail Parts offers high -level organic LCC and high -temperature brake pads. These brake pads have excellent friction stability and higher friction material flexibility, which helps reduce the formation of hot spots on the brake discs. All these features ensure the durability of brake pads and brake discs. The Kingrail Parts team cooperates with railway operators, brake system suppliers and rail vehicle manufacturers to develop and optimize organic friction surface combinations for the development and optimization of cast iron and steel brake disks.

Optimized block wheel friction combination

Kingrail Parts also offers optimized block wheel friction combinations. Provide a wide range of asbestos Organic L and LL blocks for direct alternative cast iron. There are many different shapes for K blocks suitable for trains, subways, locomotives and freight applications.

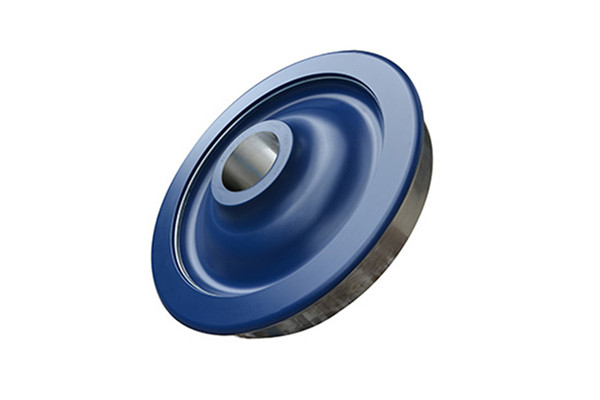

Organic railway disc brake pads

Kingrail Parts provides a wide range of asbestos-free organic brake pads, from low temperature/medium temperature to high temperature applications.

The advantages and features of the kingrail parts products include:

1. LCC friction product leading suppliers in the railway market

2. Comfortable pads can reduce hot spots, noise, discs and pads wear

3. Substation of friction stability in a very wide temperature, clamping force, axle and speed range

4. Suitable for all types of cast iron and steel wheels and axle installations

5. Applicable to passenger trains, freight, subway and rail trams

Sintering railway disc brake pads

Kingrail Parts's sintering railway disc brake pads have the following advantages:

1. Provide a variety of sintering materials

2. A comfortable backplane design reduces hot spots, dishes and mats.

3. Provide friction materials suitable for different load levels

4. Frication stability within the range of very wide temperature, clamping force, axle load and speed range

5. Applicable to the wheel axle installation discs

6. Suitable for passenger trains and locomotives

7. The unique sintering triangle segment provides the maximum contact surface

8. Suitable steel backplate can achieve better disk temperature distribution

9. Provide sintering materials approved by UIC

Organic railway brake block

Kingrail Parts brake block provides:

1. The excellent block life

2. All materials have very good dry and wet performance, even under extreme weather conditions

3. Suitable for all standard type of steel wheels -no adverse effect on the wheel

4. A significant reduction of rolling noise, lighter than iron casting, provides more than double the service life and improves wheel durability

5. Blocks that can provide UIC standard shapes can provide other references according to the requirements

6. Provide block -shaped materials approved by UIC

Kingrail Parts provides friction products suitable for any application, providing cost -effective choices to support your business.

Experience and support of global development engineering professional knowledge in the field of passenger cars and trucks. This cooperation can ensure the best friction product for the development of the highest efficiency as the rail vehicle.

Drop Messages

Please contact us with any concerns or questions you have.